Access control begins with door hardware. And with that comes a world of confusing nomenclature that can be intimidating. Welcome to Door Hardware 101, a guide to help you understand and talk about mechanical and electrified hardware.

There are four main steps to specifying door hardware: (1) hang the door, (2) secure the door, (3) control the door and (4) protect the door. This guide will explain some of the key terms used in each of these four steps.

Hang the door

Hinges or pivots?

Typically hinges are used to hang the door. There are a few basic types. Five-knuckle or three-knuckle are common choices.

Continuous hinges run the entire length of the door and are often used on exterior doors.

Pivots are used to hang the door when the door is heavy, the design of the door/frame requires pivots or because of an aesthetic preference.

Secure the door

Mechanical locks: There are many types of mechanical locks: tubular, cylindrical, mortise, interconnected and deadbolt. Below are the pros and cons of each type.

Tubular: Tubular locks have a center spindle assembly that extends through the center of the lock body and latch, allowing for retraction of the latch when the lever or knob is rotated. While this type of lock is very common on interior doors and in residential applications, they are considered the least secure lock type.

Cylindrical: Sometimes called bored locks, cylindrical locks are sturdier and considered more secure than tubular locks. The latchbolt assembly interlocks with one side of the lock chassis, making it easier to install, replace and rekey. Cylindrical locks are also available in different formats that provide various levels of security, all of which use the same type of key. This allows like-keyed and master-keyed systems that use a wide variety of locks. Cylindrical locks are vulnerable to security threats that use force to break them in two pieces–known as lock snapping or cylinder snapping.

Mortise: Mortise locks are considered even more secure than cylindrical locks. They require a pocket—the mortise—to be cut into the door where the lock is fitted. The mortise assembly includes the following:

- Lock body (the part installed inside the mortise cut-out in the door)

- Lock trim, which is typically available in various knob, lever, handle set and pull designs

- Strike plate

- Keyed cylinder to operate the locking/unlocking function of the lock body

Mortise locks are stronger and heavier duty than cylindrical locks, making them ideal for use in hospitals and schools. They are heavy enough to support ornate and solid cast knobs and levers. Mortise locks also provide a wide variety of choices for function, trim, keying systems and finishes, allowing for architectural conformity with the design of the building or locks and door hardware already on site.

Interconnected: An interconnected lock is comprised of two locks that are connected together so operating the lever handle will retract both the latchbolt and deadbolt simultaneously. The latchset is either a cylindrical or tubular lock, and there is a deadbolt above. These locks are most commonly used on dwelling unit entrance doors in multifamily residential buildings.

Deadbolt: Deadbolts, also called deadlocks, are available with a single cylinder or a double cylinder. The single cylinder deadbolt operates by a key on the outside and a thumbturn on the inside. A double cylinder deadbolt requires a key for unlocking on both sides of the door, and cannot be used on doors that are required for egress, except in certain locations where key-operated locks are allowed by code. With the exception of residential dwelling units, deadbolts are typically not allowed to be used on a door with another lock or latch installed, as the egress code requirements mandate one motion to unlatch an egress door.

Electrified hardware: Fail safe or fail secure

Electrified hardware uses power to control the locking and unlocking of the door. Most electrified hardware is available in one of two functions: fail safe or fail secure. Fail safe and fail secure refers to the status of the secure side (key side, outside) of the door. Most electrified hardware allows free egress from the egress side (inside) of the door.

Basic definitions:

- Fail safe: Power off = Unlocked

- Fail secure: Power off = Locked

An electric strike replaces the regular strike for a lockset or panic hardware. It is used as part of an access control system to provide added security and convenience such as traffic control and remote release. An electric strike is typically paired with a storeroom function lockset or panic hardware, so access is controlled by the electric strike.

An electromechanical lock is a lockset that has been electrified so that it can be controlled by a card reader, remote release or other access control device. Most electromechanical locksets allow free egress at all times.

An electromagnetic lock is an electromagnet that mounts on the frame, with a steel armature mounted on the door. When power is applied to the magnet, it bonds to the armature, securing the door. Electromagnetic locks are only available fail safe. When you remove power, the electromagnetic lock unlocks.

Tips:

- Fail safe locks should be used on stairwell doors requiring re-entry and any other doors which must allow free access upon fire alarm or power failure.

- Fail safe electric strikes can’t be used for stairwell re-entry, because fire door assemblies require fail secure electric strikes for positive latching. (Fire doors do not require fail secure electric locks—only fail secure electric strikes.)

- Be aware that when a fail safe product is used, the door will be unlocked whenever power is removed. For example, it would be removed during a power outage and, in some systems, during a fire alarm.

- Electromagnetic locks are only available fail safe.

- Electric latch retraction panic hardware is only available fail secure.

- Fail secure products are more common than fail safe due to security concerns. Fail secure products provide security when there is no power applied.

- Most electrified products, with the exception of electromagnetic locks, allow free egress at all times, regardless of whether they are fail safe or fail secure.

Types of electronic locks

An electronic lock is controlled by a reader, such as a keypad, card reader or biometric terminal. If the user has the right personal identification number (PIN), card or biometric, the door unlocks. There are two main types of electronic locks: standalone and networked.

- Standalone locks/readers: Standalone electronic locks use the same credential (card, code, etc) as networked locks. However, they are not connected to access control software, so they require the user to physically go to each lock to administer access rights and retrieve tracking information.

- Networked locks: Networked electronic locks are connected to an access control system. They allow the system manager to easily change access rights and track movement throughout the facility from anywhere they are connected to the network.

Credentials are key

Credentials are the tools that give you access. Although modern security systems use different types of credentials, a key is the most widely recognized. When they are lost, new ones must be duplicated and, frequently, locks must be rekeyed.

- Patented key management system. With a patentprotected key management system, keys are only available to authorized individuals through professional locksmith channels to prevent unauthorized key duplication.

- Cards as keys. These credentials overcome the costs and security challenges of key turnover. Options include smart, proximity and magnetic stripe credentials, each with varying levels of security. If a card is lost, its number is simply erased from the system, and the user receives a new card and number.

- Biometrics as keys. A biometric reader uses your body as identification. Your hand, for instance, can be placed on a reader. If it matches the template created when you enrolled, you get access. Biometrics provide the highest security and greatest convenience.

- Readers. Just as a key fits a lock, a card or biometric requires a reader, which is typically located next to a door. In some cases, the lock and reader are combined into one unit. When purchasing a card reader, it should have the capacity to read all types of cards: smart, proximity and mag stripe. Purchasing a multi-technology reader can eliminate the expense of installing new readers should credentials change down the road.

Exit devices get people out

An exit device (also called a crash bar, panic bar, panic device, panic hardware or push bar) allows the exterior side of the door to be locked, while ensuring that people can always exit from the interior. Consisting of a spring-loaded metal bar or touchpad mechanism fixed horizontally to the inside of an outswinging door, it activates a mechanism which unlatches the door, allowing occupants to leave quickly when the lever is either pushed or depressed. Panic hardware is required for doors which lock or latch, serving assembly and educational occupancies with an occupant load of 50 people or more (100 people or more for some codes), and also for high hazard occupancies.

There are several types of exit devices:

- Touchpad: Touchpad exit devices are mounted on the inside of the door and feature an enclosed mechanism case with a touchpad to allow egress.

- Crossbar: Crossbar exit devices may be used for doors withlarge glass lites, or where there is an aesthetic preference for the crossbar style. Available for both wide and narrow stile doors, they are ideal for environments that demand a traditional look that’s durable enough to withstand rugged applications.

- Recessed: Recessed exit devices are embedded into the door to maintain a low profile with sloped end caps that deflect objects away from the door and are close to being totally flush with the door when depressed.

- Rods vs. cables: Vertical rod exit devices have historically been manufactured with rods and latches that secure the door at the top and bottom. More recently, exit devices have been introduced that use a concealed vertical cables instead of rods. Concealed vertical cable exit devices are more aesthetic and easier to install and maintain than traditional vertical rod exit devices.

And it has dogging?

Dogging is a feature used in exit devices to hold the touchpad or crossbar in a retracted position, thus allowing a door to operate in push/pull mode without latching. Mechanical dogging is not allowed for fire doors, so fire exit hardware will not have the ability to be mechanically dogged. Fire doors may be dogged electrically, as long as the latches project upon fire alarm to positively latch the door.

Control the door

Door closers are aptly named

A door closer closes the door after it is opened manually, but it also controls the door to avoid slamming and to meet the requirements of the accessibility standards. There are both manual and electronic door closers. Choosing a door closer involves considering a variety of criteria. In addition to the closer’s performance in fire situations, other criteria may include resistance to opening forces (including heavy duty models for areas with high winds), control over the rate of closing, safety, durability, risk of vandalism and aesthetics. There are five basic types of door closers.

- Surface-mounted closers: These closers mount at the top of the door and frame—either parallel arm mount (push side), regular arm mount (pull side) or top jamb mount(push side).

- Floor closers: These closers mount in the floor, and the door is typically hung on pivots. Floor closers must be carefully coordinated with the floor construction and finish flooring for proper installation.

- Concealed closers: Concealed closers are mounted in the frame head, or in the top rail of the door, when aesthetics are a concern.

- High-security closers: High-security closers feature a vandal-resistant design for use where closers may be exposed to abuse or vandalism.

- Electronic closers: Fire doors may not be held open mechanically, but electronic closers may be used on fire doors to hold the door open and automatically close the door when a signal is received from the fire alarm or smoke detector. A door with this type of closer is called automaticclosing, while a door that closes each time it’s opened is called self-closing.

Automatic operators provide easy access

Low energy automatic operators are used where a “knowing act,” such as a push button, is used to automatically open the door. They are required by code to open the door slowly and with a limited amount of force. Therefore they do not require the safety sensors and rails required for full-powered operators like the operators seen on a grocery store entrance.

Electro-hydraulic systems: These are designed for manual opening applications where there is occasional need for automating the door to meet ADA requirements. Electrohydraulic operators combine a conventional heavy-duty door closer with a low-energy automatic operator.

Electro-mechanical systems:

Pneumatically powered systems: These are great for use in areas where electrically operated devices are not convenient or permitted. The pneumatic operator consists of a heavyduty door closer for manual operation and a pneumatic automatic operator to power the door when required. Power for the operator comes from the in-house air supply or a compressor furnished with the operators. These operators are silent when the compressor is installed in a remote location, making them ideal for use in libraries, churches, hospitals and laboratories.

Protect the door

There are many types of products designed to protect the door from wear and tear, including protective plates, push plates and pulls, edge guards, stops, gasketing and thresholds, and other miscellaneous products. When strategically placed on the door, these items can reduce abuse and wear of the door.

Working with a specification consultant

Some architects like to specify hardware, but we’ve met many who find it tedious. Product numbers and codes change, and integrating the various hardware products has become increasingly complicated. Mistakes can be costly and often impact construction schedules if they’re discovered late.

Whether you write your own specs or work with an architectural consultant, knowing the jargon for door hardware will help ensure your next project is safe and secure.

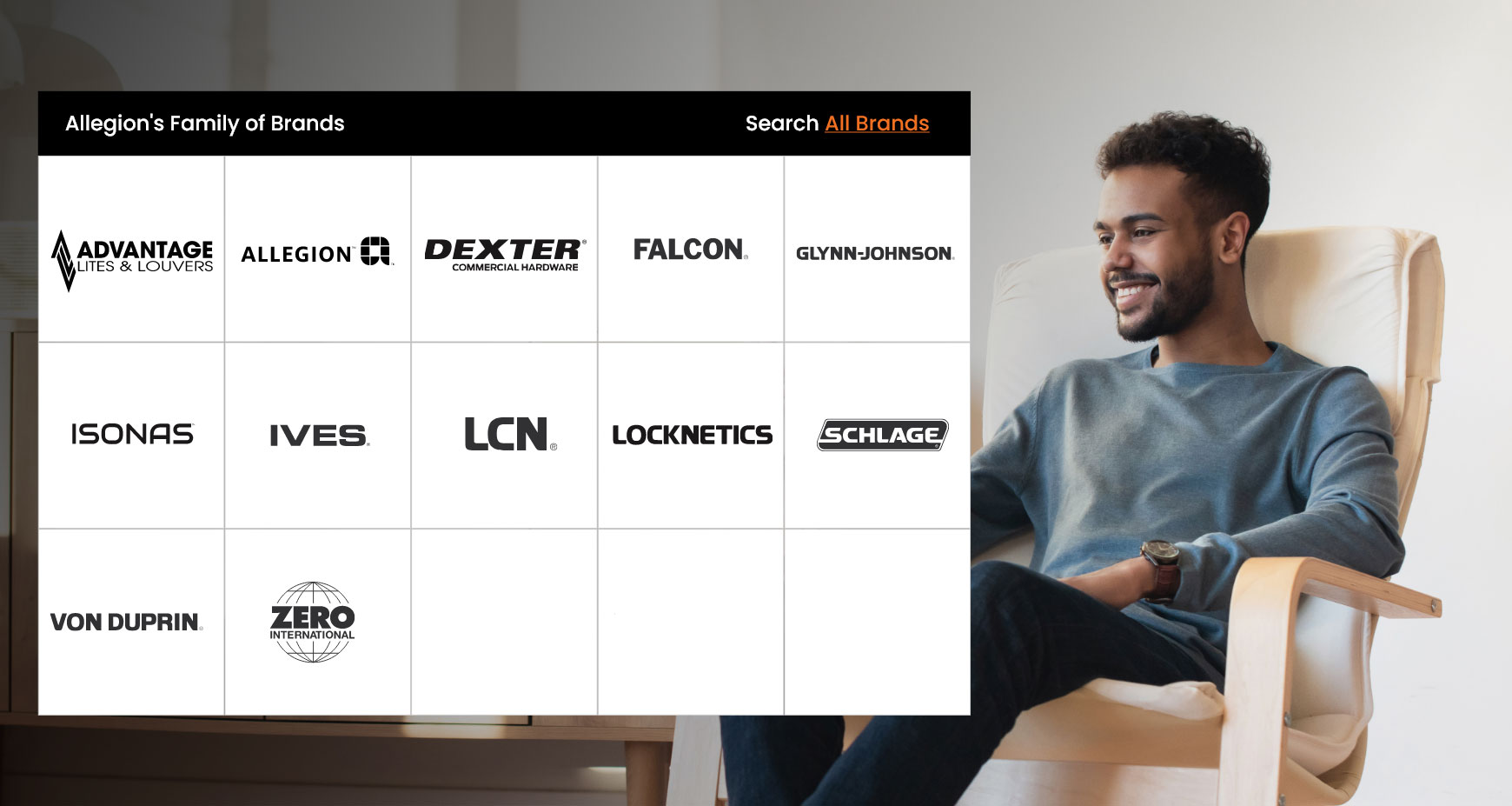

Allegion has a team of more than 150 specification writers located around the world who would be happy to assist on your next project. Contact an Allegion specification writer, or check out the iDig Hardware blog for information and updates on door hardware codes.

Find these back-to-basics articles interesting?